Manufacturing system

Policy / system

- Quality policy

- It is expected that customers’ interest in health will continue to grow. In order to meet such demands, we have established the following quality policies.

1. Make products from the customer’s point of view with sincerity.

2. Work is constantly being improved to eliminate waste.

3. Each employee should always work with an awareness of quality improvement and production efficiency improvement.

- Collaboration with R & D

- At the Fine Bioscience Research Center (FBRC) on the premises of Osaka University, we are constantly searching for new functional materials that will be the basis of new products. The results obtained there are passed through commercialization research, safety tests, stability tests, etc., and then prototypes and tests are repeated at our factory, and are utilized in the manufacture of products. Through this industry-academia collaboration system, we provide genuine health foods that can contribute to extending healthy life expectancy.

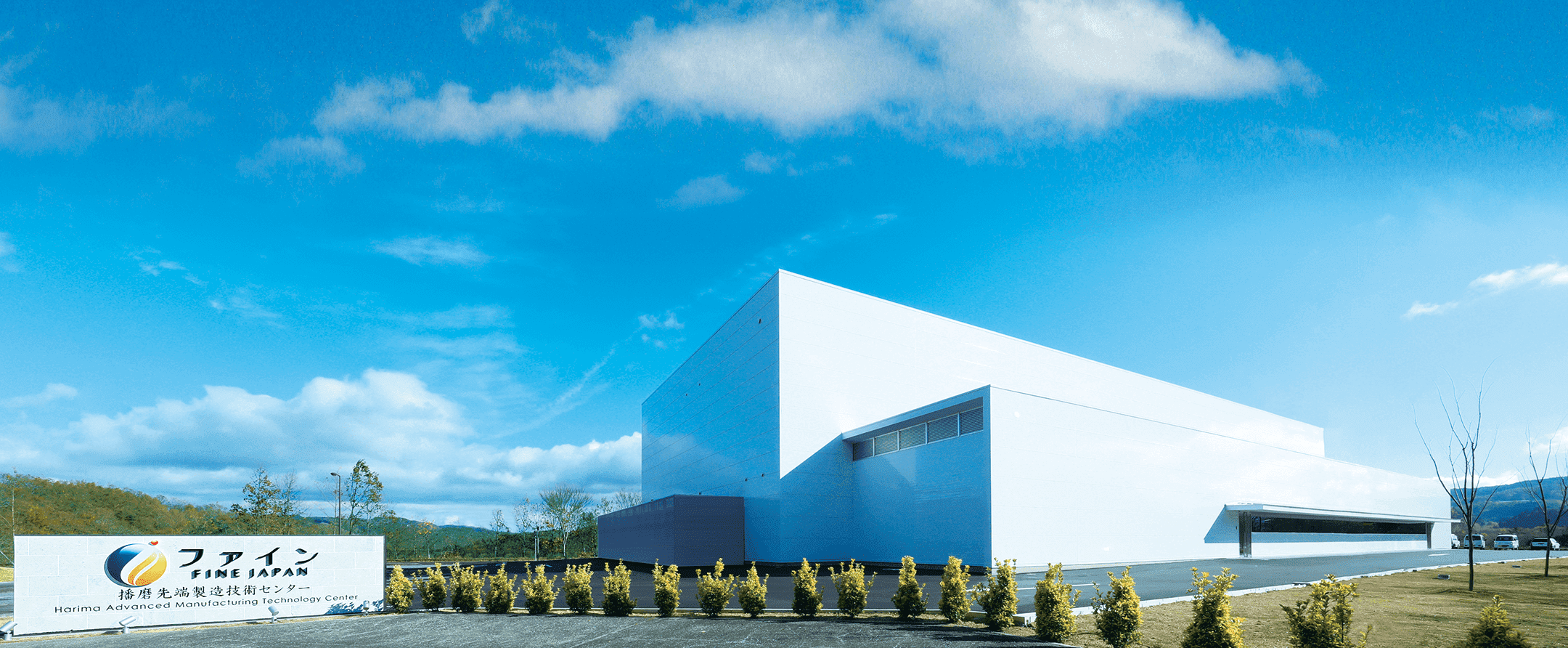

- To an open factory

- A tour passage has been set up on the first and second floors of the Harima Advanced Manufacturing Technology Center (HAMTC), which is the core factory, and some production processes are open to the public. We are planning an event where we will explain in an easy-to-understand manner to our customers and customers how our products are made, and to sample and sell them directly. In addition, we will actively hold tours of our factory for children and would like to contribute to the community through such educational activities.

Quality control

We have established a quality assurance system to pursue food safety.

Dietary supplements GMP, ISO9001, organic JAS

Our factory guarantees the quality and safety of final products based on dietary supplements GMP, ISO9001 and organic JAS.

dietary supplements GMP

dietary supplements GMP ISO9001

ISO9001 Organic JAS.

Organic JAS.

Obtained manufacturing license

When manufacturing products that fall under the “pharmaceutical products,” “quasi-drugs,” and “cosmetics” under the Pharmaceutical Affairs Law, a “manufacturing license” is required for each, and to ship the products to the domestic (Japanese) market (to sell, rent or give to distributors and consumers), “manufacturing and sales license”is required. Our factory has cleared the strict examination of the Pharmaceutical Affairs Division and obtained the following permission.

- Soft drink manufacturing certification

- Confectionery manufacturing license

- Cosmetics manufacturing and sales license

- Cosmetics manufacturing license

- Quasi-drug manufacturing license

- Pharmaceutical manufacturing license

Manufacuturing flow

- STEP 1Accepting raw materials

Record information on incoming raw materials and confirm that they meet acceptance criteria. Abnormal raw materials are excluded here.

- STEP 2Weighing

Weigh the raw materials used for tableting and granule processing. We will double check to make sure there are no mistakes.

- STEP 3Granulation

It hardens powders and fine particles into granules. With the introduction of a new model, we are working to improve the physical properties of granules and shorten the granulation time.

- STEP 4Mixing

Mix multiple powders with different specific densities using a mixing inversion machine. With the introduction of new models, we are increasing the variety of finishes.

- STEP 5Tableting

We will make tablets according to the customer’s request, such as round shape, triangle shape, unique heart shape, etc. of various sizes.

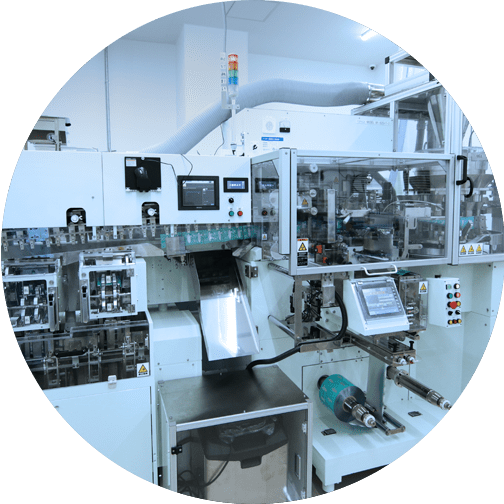

- STEP 6Filling

We have installed a high-speed sachet machine and are operating with a production capacity 13 times that of conventional products. It is a fully automated line that does not touch people.

- STEP 7Packing

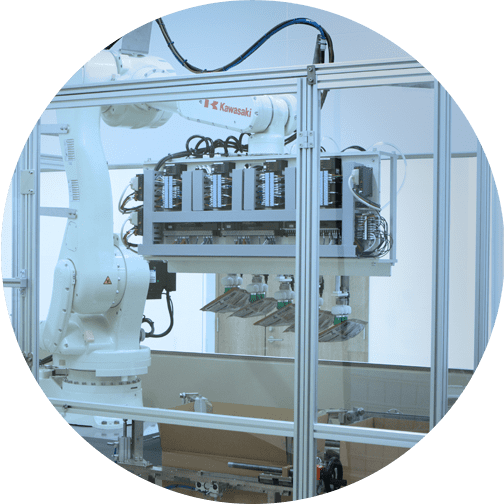

By installing a boxing automation robot instead of the conventional manual work, we are shortening the time and improving the production capacity.

- STEP 8Shipping

We will make a final check of the product, such as damage to the packaging, and ship it to the customer. And that information is recorded and stored.

Factory / equipment

Harima Advanced Manufacturing Technology Center

It was built as a core factory of FINE JAPAN CO., LTD. Our factory will increase the production capacity more than three times as much as before by introducing new automatic production lines and robots to improve efficiency. We have introduced the latest machines in each process such as granulation, mixing, tableting, filling, and packing, and manufacture products in the shortest time from receiving raw materials to shipping. Temperature control is possible in all areas, an air shower is installed, a positive pressure system is adopted in the sanitary area, and an air transportation and transportation device is introduced to realize manufacturing that does not touch people.

Main production equipmentGranulation process / Stick filling and packaging process / Mixing process /

Bag filling process / Tableting process / Large bag filling process /

Sachet process / Bottle filling finish process / Grain alpha processing machine /

Foreign matter removal line

- Formal Name

- Harima Advanced Manufacturing Technology Center

- Known as

- HAMTC

- Location

- 1-11-1 Shingucho Koto, Tatsuno City, Hyogo Prefecture 679-5165, Japan

- TEL

- +81-791-58-2655

- Completion date

- November 30, 2016

- Structure

- Steel-framed two-story building

- Site area

- 13,190.30㎡

- Number of manufactured items

- 800 items

Kamigori Factory

Main production equipment Sugar coating machine / Mixer / Dryer / Crusher / Sieve machine / High-speed rotary tablet molding machine / Powder, tablets and capsules folder / Various powder filling machines / Various liquid filling machines / Beverage production line / Liquid stick filling and packaging machine / Label machine / Stick stacker / Pillow packaging machine / Cartoning machine / Shrink wrapping machine / Auto checker / X-ray inspection machine / Various other machines

- Location

- 931 Okko, Kamigori-cho, Ako-gun, Hyogo Prefecture, 678-1219, Japan

- TEL

- +81-791-52-1776

Kamigori Techno Factory

Main production equipment

Fine crusher / Super fine crusher / Vacuum emulsifying kettle / Encapsulation material supply tank / Encapsulation material preparation tank /

Capsule contents liquid preparation tank / Tumbler dryer / Extraction tank / Filter press machine / Hard capsule filling machine / Blister packing machine / Bag filling machine

- Location

- 700-3, Nokuwa, Kamigori-cho, Ako-gun, Hyogo Prefecture, 678-1202, Japan

- TEL

- +81-0791-57-7030

Contact

and inquiries about publication and coverage.